Thermal Chuck Systems

We offer a wide range of extremly performant, reliable temperature control systems for the semiconductor industry. The modular concept for convenient, cost effective system upgrades, highest safety of investment and easy customization.

Core Technology

- Modular Design Concept

- Universal Chuck Design – one chuck for air- and liquid cooled systems

- Hybrid Chuck Design – operation with and without cooling unit

A-Series

- Air Cooled High Temp Systems

- Temperature Range: -10°C/+20°C/ambient to +200°C/300°C/350°C

C-Series

- Air Cooled Low Temp Systems: -65°C/-40°C to +200°C/300°C

- Hybrid Chuck usable for air- and liquid cooling

L-Series

- Liquid Cooled Low Temp System:-65°C/-40°C/-20°C to +200°C/300°C

- Hybrid Chuck usable for air- and liquid cooling

General Specifications

The table below shows the overall specifications overview. Chuck performance may vary between different prober types and applications. Please contact us for detailed specifications for your use case.

| Criteria | A-Series | C-Series | L-Series |

|---|---|---|---|

| Technology | Air - Hot | Air - Hot/Cold | Liquid - Hot/Cold |

| Temperature Resolution | 0.01°C |

||

| High Temp. Range: | +200°C/+300°C/+350°C |

||

| Low Temp. Range: | -10°C/+20°C/+25°C | -65°C/-40°C/+20°C/+25°C | -65°C/-40°C/-20°C/+20°C/+25°C |

| Planarity (low to+200°C) | +/- 8µm | +/- 5µm | +/- 5µm |

| Accuracy | +/-0.1°C | +/-0.1°C | +/-0.1°C |

| Stability | +/-0.1°C | +/-0.1°C | +/-0.1°C |

| Uniformity | +/-0.5°C or +/-0.5% | +/-0.5°C or +/-0.5% | +/-0.5°C or +/-0.5% |

Thermal Solutions

Advanced Temperature Test Systems means best available components for our products and the most advanced manufacturing technology. Our products are designed for exceptional thermal and mechanical stability and precision.

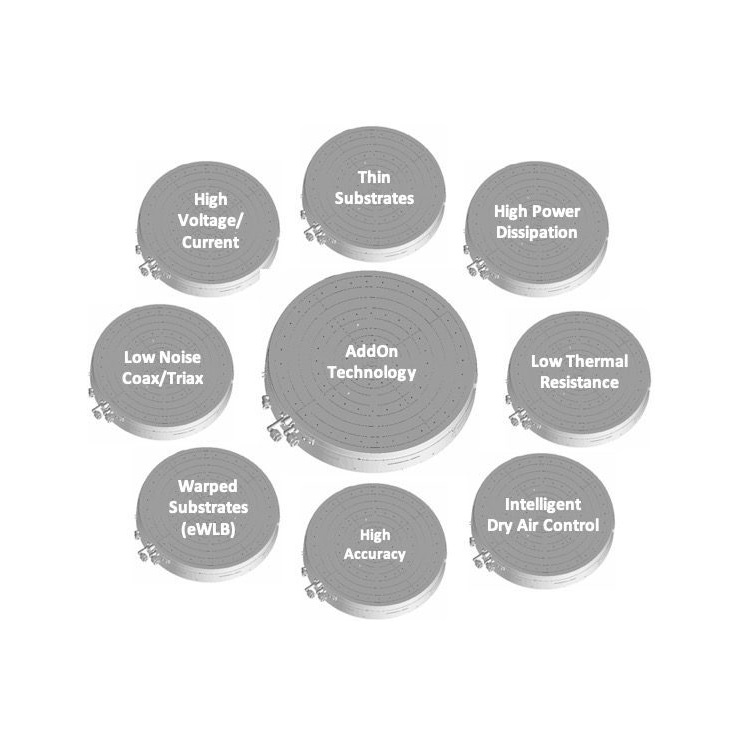

AddOn

Technology

- Modular AddOn Stacks for various applications

- eWLB, HV/HC, LN, Plain, Caro, etc..

Low Thermal Resistance (LTR)

- Low Thermal Resistance (LTR) Technology

- MultiSense Technology

- High Accuracy Applications

- High Power Applications

LTR

High Accuracy

- Low Thermal Resistance Technology

- MultiSense with multiple temperature sensors

- Designed for low power and sensor devices

- Best temperature accuracy and uniformity

LTR

High Power

- Low Thermal Resistance Technology

- For high power and high parallelism devices

- High power dissipation @ wide temperature range

IntelligentDry Air Control

- Active CDA purge control to reduce the dry air consumption

- Advanced dry air control to purge with two individual media

- Bonding pad protection

- Adaptive dew point control

Thin/Warped

Substrates

- Patented Bernoulli functionality for extremely thin wafers and substrates

- Solution for chucking of highly warped substrates (e.g. eWLB)

- Adaptive power vacuum for different chuck zones

Low Electrical

Noise

- Triax connection standard on all ATT chuck systems

- Sub-femto options available through AddOn technology

High Voltage /

High Current

- Multiple High Voltage and High Current solutions available

Services

Great Services for great additional added value!

Cold Upgrades

- On-site cold upgrades for all main prober platforms

- Liquid and Air cooled – -40°C and -55°C solutions

- 5-7 working days including prober sealing

Temperature Calibration

- On-Site chuck temperature calibration service

- Utilizing certified calibration wafers

- Contact us for a detailed proposal

Preventive Maintenance

- Preventive Maitenance offerings for our thermal chuck systems

- Contact us for a detailed proposal

Service Contracts

- Various service/support contract offerings

- Contact us for a detailed proposal